Bar Bending Schedule

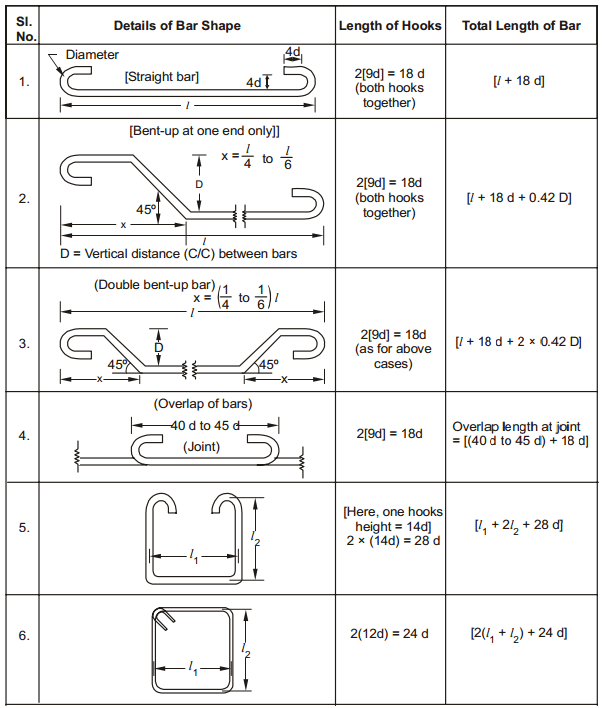

Bar Bending Schedule is the extended presentation of cut and bend bars as per the design requirements of reinforcement detailer. It’s a list of reinforcing for the tasks to be carried out. It lists location of the bar, bar mark, diameter of bar, number of pieces, length before bending, shape code and several lengths of the bent shape and it gives perfect idea to the manufacturer where to bend it. Going by the schedule along with the structural drawings, the workers can install the structural in correct manner.

ADVANTAGES OF BAR BENDING SCHEDULE

- The cutting and bending of reinforcement can be done at factory and transported to site upon the availability of Bar Bending Schedule. This enhances faster execution at site and lessens the time of construction and cost due to fewer requirements of workers for bar bending. With accurate bar bending schedule, one can avoid the wastage of structural reinforcement up to 10% thus saving the cost for the project.

- It offers better estimation of reinforcement structural requirement for each and every structural member which can be used to compute overall reinforcement requirement for the entire project.

- It enhances the quality control at site as reinforcement is offered as per BBS which is made using the provisions of respective detailing standard codes.

- There is a general propensity to group slabs and beams in the usual design methods. In BBS, it’s essential to detail every member separately to account finer geometry and different forces coming on the structure in the modern design methods.

- One can use BBS for the cutting and bending of reinforcement and making skeleton of structural member before it can be placed at the position required. Other activities such as PCC, excavation etc. can proceed side by side with this activity. This propels reduction in time of construction and also the overall project activity management becomes easy. It also becomes useful in preventing any damages due to construction time overrun.

- BBS makes life easy for site engineers to validate and approve the bar bending and cutting length during review before placement of concrete thus helping in better quality control.

- It lets easy and quick preparation of bills of construction works for clients and contractors.

- Mechanization of cutting and bending of reinforcement can be done with the use of BBS, thus lessening the time and cost of project and reliability on skilled labour requirement. It also enhances the reliability on precision of bar cutting and bending.

Generally, civil engineers who have expertise in RCC structure are the ones to prepare the BBS. Preparing BBS requires more time for calculation compared to common quantity take offs. These calculations comprise of cutting length, deduction of bend allowance within cutting length and summary of weight of each size separately. Mercury Rebar has all the required expertise to prepare the BBS as per the requirement of the project and in accordance with the inputs given by the client.

Work Samples

Copyrights 2018. All Rights Reserved. Powered by: InnoMind Technologies